Back to top

Your one-stop solution for all your office supplies, Universal Board Display Stand, Magazine Display Stand, art supplies, educational aids, display & drawing stands, training & presentation accessories and interactive classrooms needs. Visit www.pragatisystems.in for more information.

About Us

Nurtured from the seed of a single great idea- to provide educational aids at affordable rates, Pragati Systems went on to pioneer the entire Office Supplies and Educational Aids industry in India. What started as a small stationery outlet in central India in 1957 has now evolved into a group of companies (visit www.pragatisystems.in for more details) based out of Indore, all working together in harmony to achieve their common goal- to make knowledge sharing easier and inexpensive by delivering high-quality products. After all, education is the most powerful tool which can be used to change the world and make it a better place for living. At Pragati Systems, we manufacture a range of office supplies, art supplies, educational aids, display & drawing stands, training & presentation accessories and interactive classrooms. We deliver world-class products and services by combining technical expertise, quality commitments, and innovation. At heart, we are a customer-centric organization built on the foundation of business-friendly policies and motivated individuals, a blend that allows us to achieve 100% customer satisfaction.

Our Presence

- Domestic presence in 26 Indian states through a well-established dealer network.

- International distribution across Asian, African, European and American countries.

Our Promise

- 100% Manufactured in India

- 100% Quality Assurance

- 100% Customer Satisfaction

Quality Products

We have gained an immense trust of our valuable clients by offering them only quality assured products. Owing to our market value, we aspire to surpass the quality standard we already work by. We use premium grade raw materials to achieve excellence through our product range. Our highly qualified quality inspectors ensure maximum quality in all manufactured goods. Thus, we never compromise on the quality graph we have created with years of expertise in our domain.

Plant and Manufacturing Capabilities

Our plant is equipped with Machine Shop, Tool Room, Fabrication Shop, Paint Shop and Assembly Line. The machine shop has equipment like Drilling Machine, Lathe Machine, Milling Machine, Internal Grinding Machine, External Grinding Machine, Surface Grinding Machine, Injection Moulding Machine, etc. The tool room is fully equipped to design any tool, jig and fixture. Our qualified R&D/Tool Room supervisors along with in-house CAD facilities make the process perfect and quick. At Pragati Systems, we believe in exploiting the most advanced technology to achieve the company objectives. Our engineers use CAD/CAE tools for the complete modeling as well as optimization of the designs. The fabrication shop has equipment like Shearing Machine, Mechanical Press Brake, Hydraulic Press Brake, Power Presses of different capacities, Corner Notching machine, TIG welding, MIG welding (for welding of Copper, Aluminum, M.S. & S.S. jobs), Spot welding, Electric Arc welding, Pipe cutting and bending equipment, all types of electric and pneumatic hand tools, Iron Worker and CNC Laser cutting machine. The paint shop is equipped with pre-cleaning tanks, pre-treatment tanks, Compressors, Spray Gun, Painting Booth and Oven. Two methods of Painting Electrostatic Powder Coating and Oven Baked Spray Painting guarantee a superior and durable finish. Environment friendly Powder Coatings are available in Epoxies, Urethane & Polyesters in a wide range of standard and custom colors.

Management

The organization has a team of dedicated, committed workers and professionals, having experience in their respective fields. Accounts, Office Management, Stores, HR, Sales, Production, and Front Office all are managed through ERP solution. This ensures precise and instant availability of information to our suppliers, working team and customers for trouble free and smooth business dealings.

Man Power

For accurate, time bound & efficient working we have a team of I.T.I trained workers, diploma holder supervisors and design engineers. Our designers use modern CAD/CAM softwares for designing of products and processes. All the design alternatives are checked through various simulations on CAE softwares. Final model can be checked for feasibility before taking up the actual production. Our sales personnel have full working knowledge of all plant processes and capabilities. They are responsive to customer demands and requirement. They work directly with production and engineering to be your advocate. Your product is the prime concern.

Product Portfolio

We specialize in manufacturing a chain of office equipments, notice boards and similar products. These products also are adjustable in height and also come in various sizes to suit demands of different industries. All our products are listed in the following part:

|

Ammonia Printing Machines |

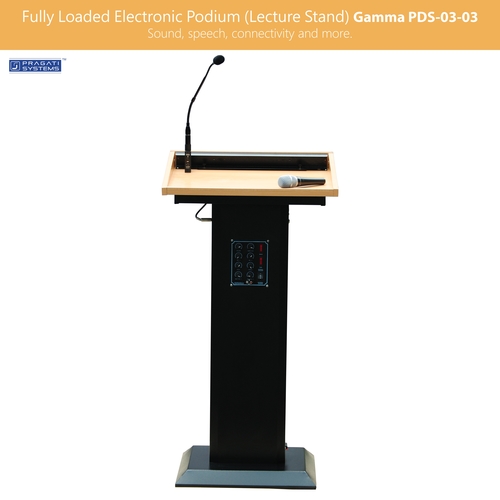

Podiums |

|

Art Material |

Projection Trolleys |

|

White, Chalk & Display Boards |

Projector Mounts |

|

Notice Boards |

Classroom Furniture |

|

Drawing Material |

Stands For Writing & Display |

|

Drawing Office Equipment |

Display Utility Stands |

|

Drawing Stands |

Educational Aids |

|

Easels |

Illuminators/Scrollers |

Send Inquiry

Send Inquiry Send SMS

Send SMS